Beautiful Info About How To Control Haccp

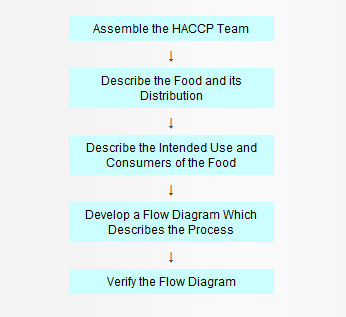

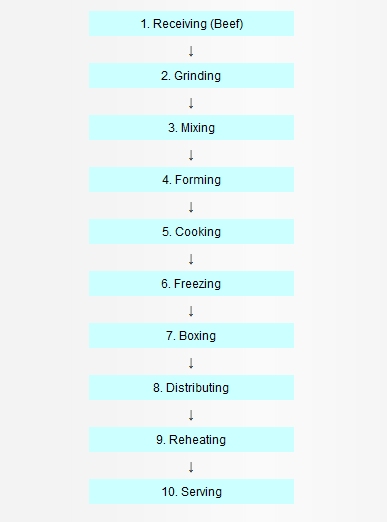

Writing a haccp plan involves preoperational steps such as.

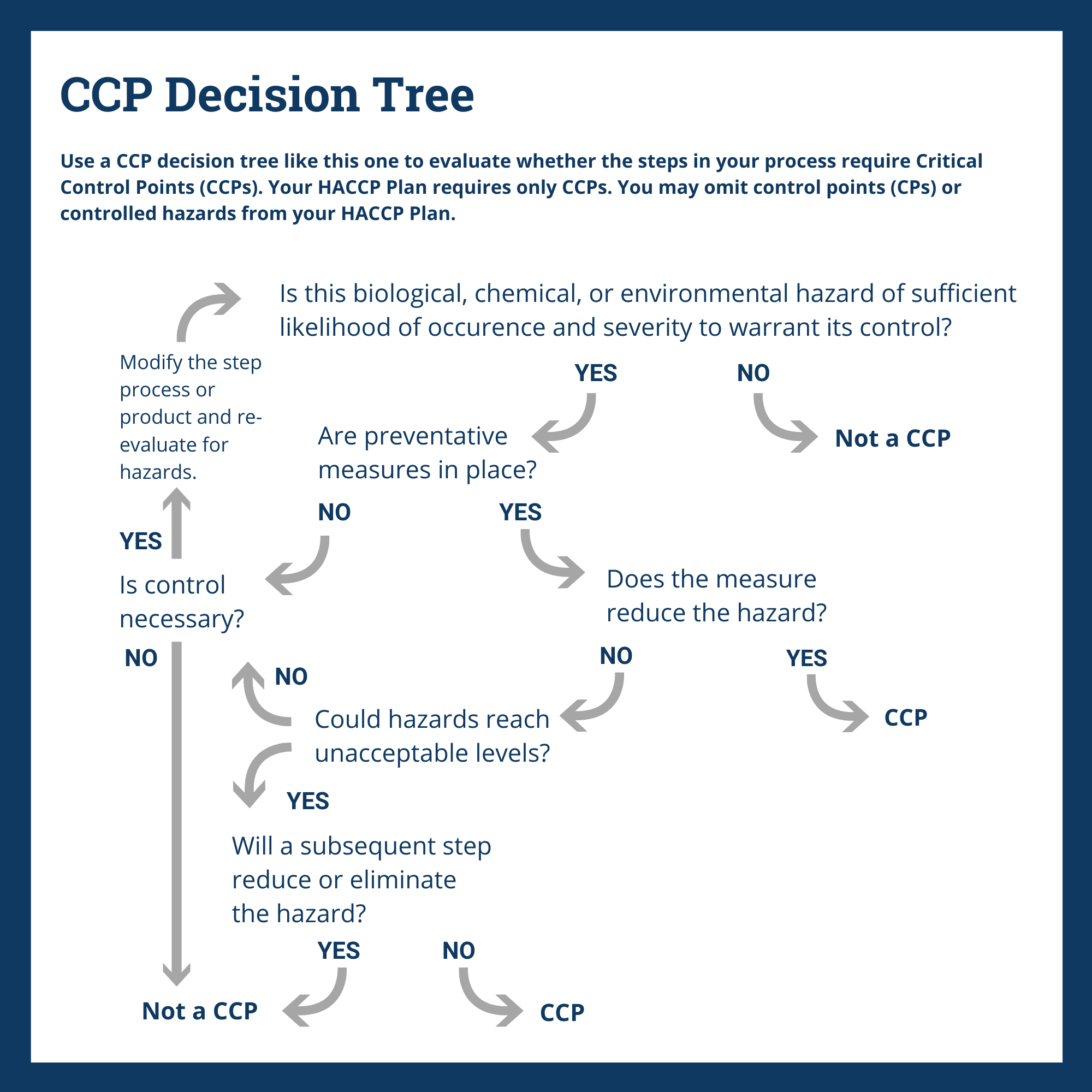

How to control haccp. All hazards—both potential or previously demonstrated—that may occur in each. A step in a food production process at which a control can be appliedto prevent , eliminate, or reduce a food safety hazard to acceptable levels. A safety hazard may require several control measures.

Haccp systems addresses food safety through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to. Effective hazard identification and hazard analysis are the keys to a successful haccp plan. Establish critical limits your next.

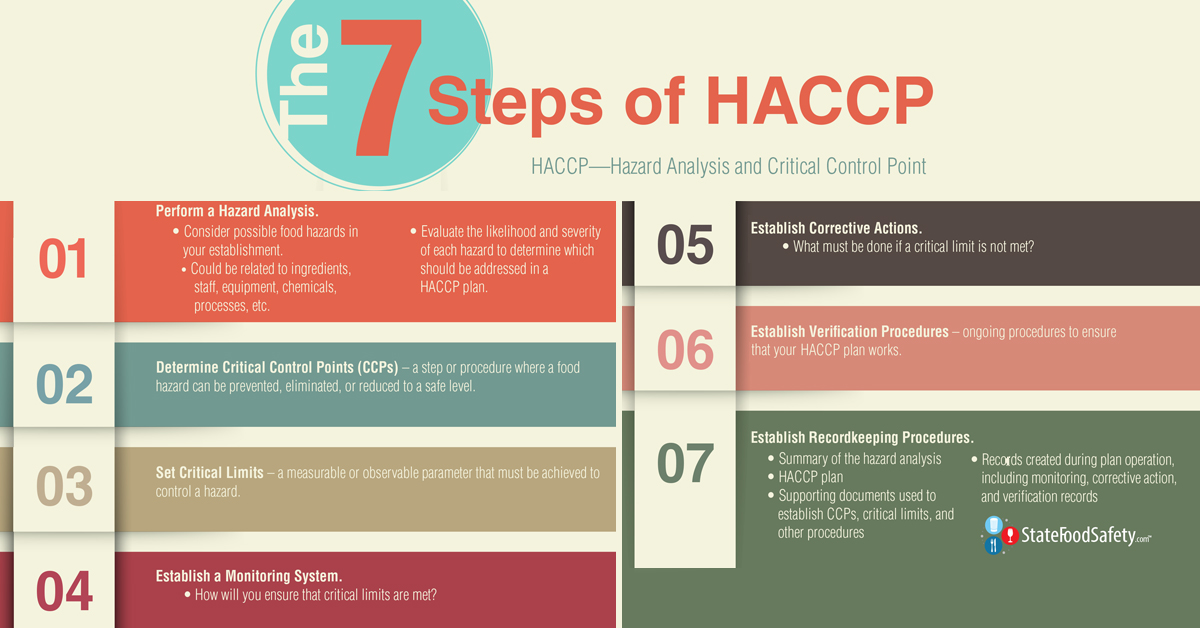

The second principle in the haccp process is to identify critical control points. On the other hand, a single control measure can handle multiple hazards, as in the case of the pasteurization of milk. Haccp is a systematic approach to the identification, evaluation, and control of food safety hazards based on the following seven principles:

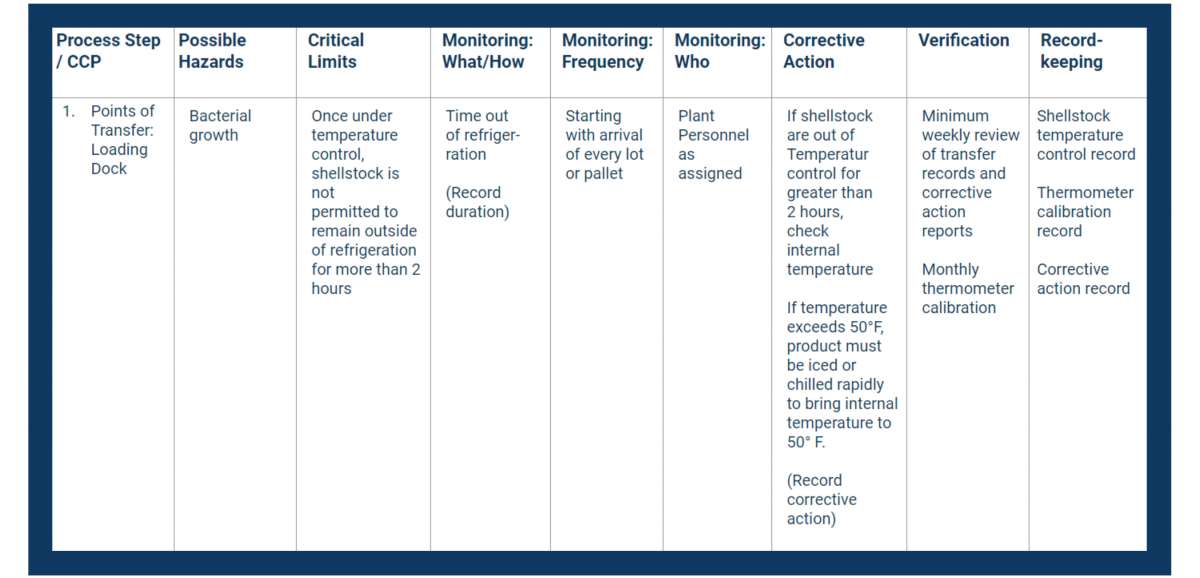

This includes documenting the haccp plan which. Having identified specific hazards, you need to set up control points where that hazard can be prevented or its risks minimized. One of the keys to developing a good haccp allergen control program is the identification of which allergens can potentially contaminate your food products.

Writing a haccp plan is crucial in keeping control of food safety in the food industry. The haccp team should establish procedures and records to ensure adequate food safety controls are in place. Use of specific temperature, ph, time, procedures?

A critical control point is defined as a point, step, or procedure in a food process at which control can be. A hazard is controlled by one or more critical control points (ccps). For each critical control point you will identify the preventive measure.